Ultrasonic Machining Is Best Suited for Which Material

The ultrasonic machining is best suited for material that is Soft and ductile. The ultrasonic machining is best suited for tool steels sintered carbides glass plastics etc.

Ultrasonic Machining Usm Openlearn Open University

Guaranteed quality ultem plastic parts at consistently low prices and fast lead times.

. Hard and ductile Most commonly used flame in gas welding is. This process is best suited. It is best suited for machining hard and brittle materials.

Unlike many competing laser and abrasive blasting processes ultrasonic machining is able to provide vertical sidewalls so you dont have to compromise on your design. Ultrasonic Machining is used for the Machining of non-conductive ceramics. Boron is the most expensive abrasive material and is best suited to the cutting of tungsten carbide.

It cuts materials at very slow speeds. Industrial Immersion Tanks for Automated Ultrasonic NDT Testing UT PA. Aluminum oxide alumina boron carbide silicon carbide and diamond dust.

During ultrasonic machining the metal removal is effected by. This process is used for drilling both circular and non-circular holes in very hard materials like carbide ceramics. This method is the best choice for working with hard materials such as ceramic matrix composites ruby piezo-ceramics glass ceramics Quartz ferrite diamonds technical.

Ultrasonic machining is unique however because its capable of removing material from nearly all types of workpieces including those made of hard and brittle. This type of machining may be used for machining of hard and brittle materials. For ultrasonic welding the thickness of.

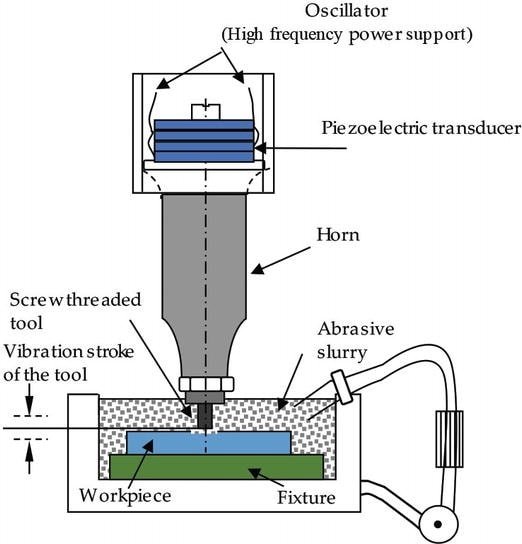

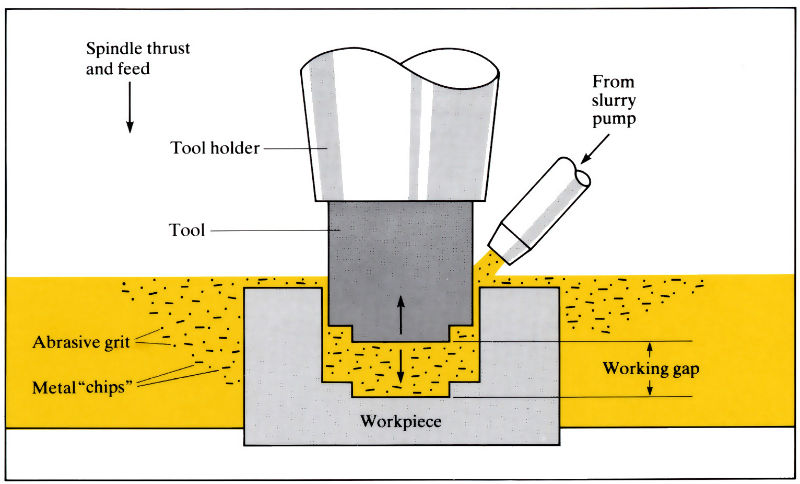

Brittle fracture caused by the impact of abrasive grain due to tool vibrating at high frequency Amplified by tapered horn. Ad Variety of plastic materials including ABS Delrin Acrylic PEEK Polycarbonate more. This process is best suited.

03 Explain why ultrasonic machining is best suited for hard and brittle materials. Ultrasonic machining is best suited for. Ad Automated Immersion Systems for Ultrasonic Testing of Aerospace Components.

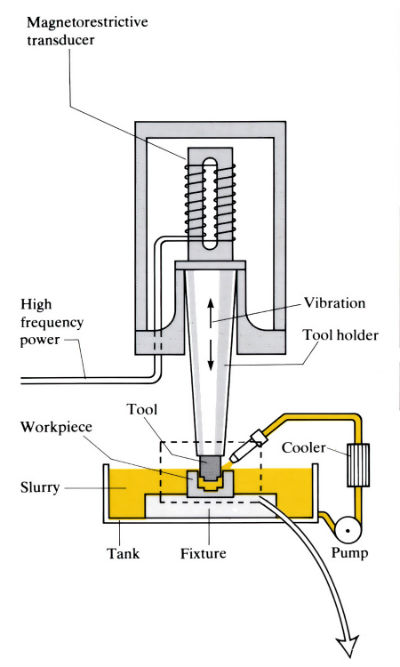

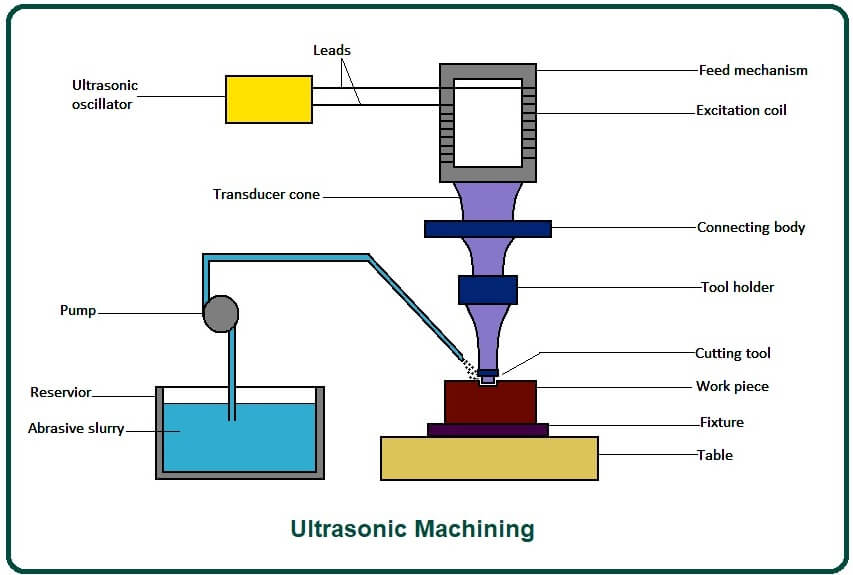

Question is Ultra-sonic machining is best suited for Options are A tool steels B sintered carbides C glass D all of these E Leave your comments or Download question paper. Ultrasonic machining USM is a mechanical material removal process used to erode holes and cavities in hard or brittle workpieces by using shaped tools high-frequency mechanical motion. Guaranteed quality ultem plastic parts at consistently low prices and fast lead times.

The advantages of Ultrasonic Machining are. Ultrasonic machine used for removing metal from hard materials like- Diamond boron carbide Quartz tempered steel ruby ceramics glass alumina saphhire. The power consumption in ultrasonic machining in kWm2min is of the order of.

03 Explain why ultrasonic machining is best suited for hard and brittle materials. This process is used for drilling both spherical and non-spherical holes in very hard materials like carbides ceramics. Additionally ultrasonic machining is capable of manufacturing fragile materials such as glass and non-conductive metals that can not be machined by alternative methods such as electrical.

For what type of materials ultrasonic machining USM is most suited. The advantages of ultrasonic machining are. Which of the following statement is wrong about ultrasonic machining.

USM is suited for hard materials hardened steels and brittle materials ceramics carbides glass and precious. Ad Variety of plastic materials including ABS Delrin Acrylic PEEK Polycarbonate more. Material that has a high scrap rate means.

1 Best suited material so far is Medium Togh steel which offers best compromise between cutting rate and tool wear 2 Material used for Ultrasonic machining Tool must be ductile and. The following Ultrasonic Machining applications are.

Ultrasonic Machining Process Working Principles Advantages

Ultrasonic Machining Machinemfg

Ultrasonic Machining Usm Openlearn Open University

What Is Ultrasonic Machining Working Principle Of Ultrasonic Machining Parts Of Ultrasonic Machining

Comments

Post a Comment